Project lead: Murdoch University

Project overview

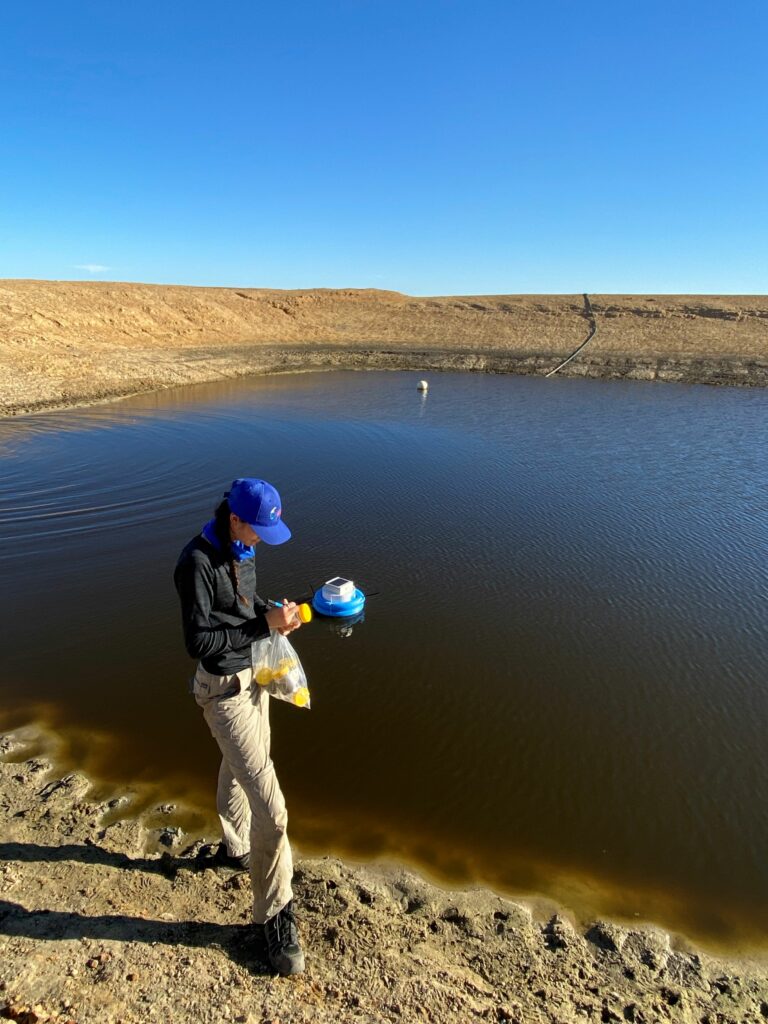

In broadacre crop production in Western Australia, the average plant water use efficiency stands at just 56%. This suggests significant potential for further economic benefits if innovative solutions can be developed to capture water within the plant root zone. Optimising water use is crucial for the region as climate predictions indicate that the south-west of Western Australia will continue to experience a drying climate and increased variability in rainfall patterns.

SMART SPRAYS will transform broadacre crop production by improving water harvesting (into furrows) and water retention (less evaporation) in regions where water efficiency is low. In doing so, the SMART SPRAYS technology will decrease the risk of plant water stress during the growing season and increase plant water use efficiency.

Expected outcomes

The project aims to illustrate the capacity for the SMART SPRAYS technology to increase rainfall capture into the soil and through to the plant.

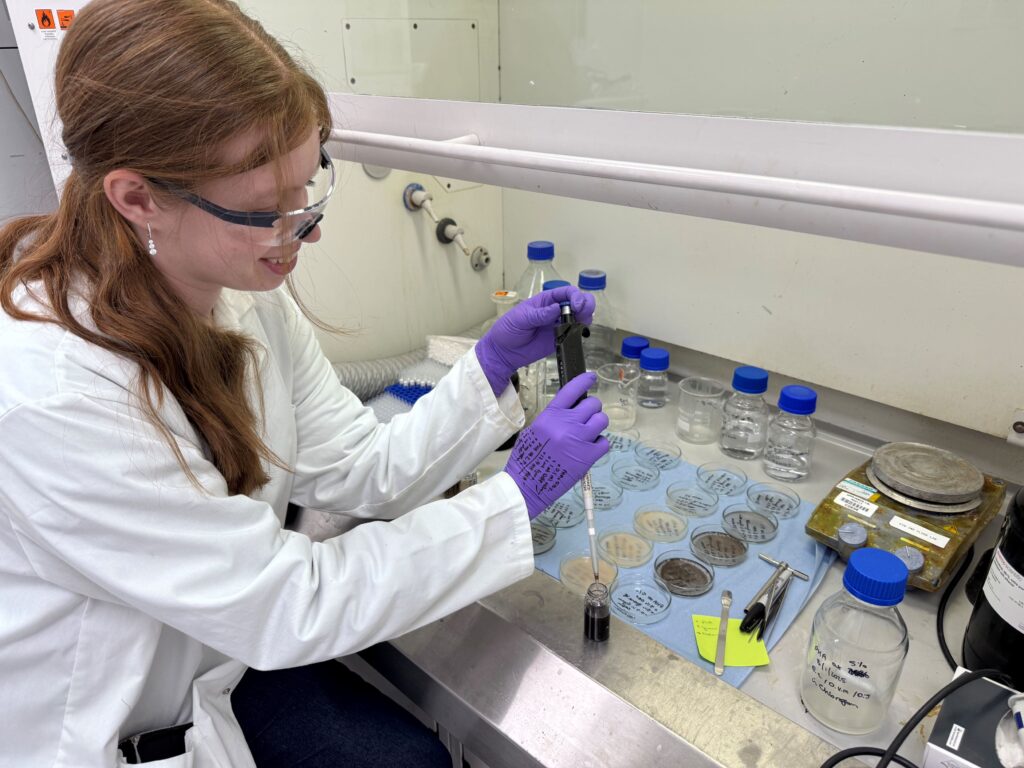

Activity 1. This project will demonstrate and test (from laboratory to field) a non-toxic, bioplastic-based spray that forms a water barrier that can be easily applied with existing farm equipment. This technology will be assessed for its capacity to harvest rainfall from the mound into the furrow and decrease water evaporation from within the soil.

Activity 2. This project will assess the ease of use of the SMART SPRAYS technology, particularly its ability to be deployed with existing farm infrastructure with minimal modification.

Activity 3. This project will assess the capacity of SMART SPRAYS to increase crop productivity. This is of critical importance to the region as climate predictions indicate that the south-west of Western Australia will continue to experience a drying climate.

This project seeks to answer the following questions:

- How can more rainfall be converted into a saleable product (food, feed, fibre, fuel)?

- How can Australia combat a declining rainfall through greater retention and use of available water?

This project is supported by the South-West WA Drought Resilience Adoption and Innovation Hub, through funding from the Australian Government’s Future Drought Fund, Murdoch University and the WA Agricultural Research Collaboration

FAQ

Smart sprays have the potential to reduce evaporation and redirect water for increased crop yield and profit.

Smart sprays components:

- Biodegrade in marine, soil, and compost environments into CO₂, water, and biomass.

- Do not degrade into microplastics in the environment.

- Reduce reliance on fossil fuels and have a decreased carbon footprint as no fossil fuel feedstock is used.

- Do not need to be retrieved from the field – they will biodegrade in situ.

The main component of SMART SPRAYS can be produced by microorganisms through the use of a wide variety of renewable feedstocks, like organic wastes, waste canola oil, brewers waste and glycerol, creating a circular economy.

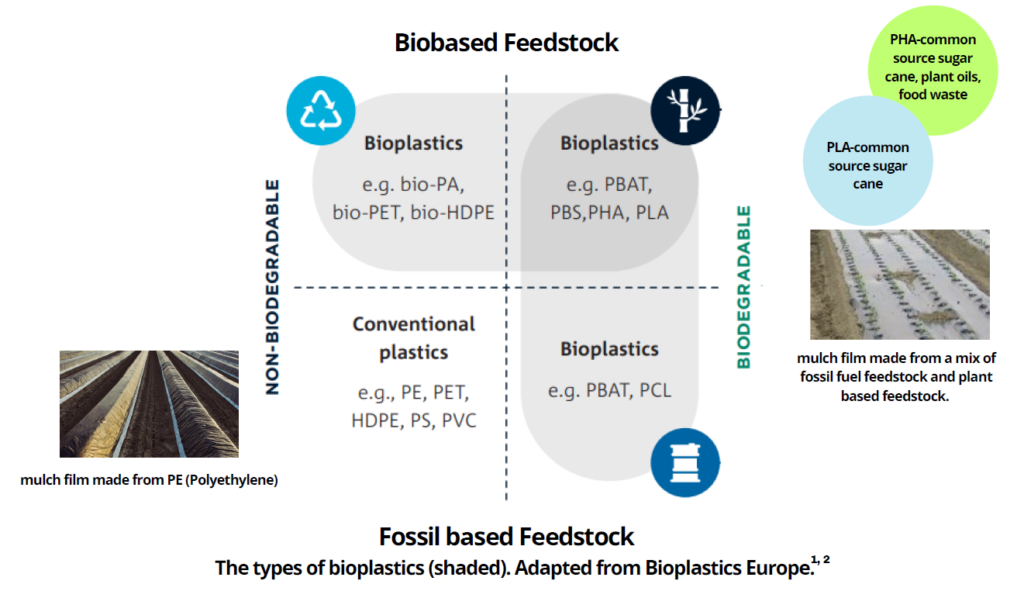

Plastics and bioplastics can be categorised based on their origin/feedstock (biobased vs. fossil fuel based) and their degradation properties (biodegradable vs. non-biodegradable).

Feedstocks

Fossil-based feedstocks: Derived from petroleum, natural gas, or coal.

Biobased feedstocks: Derived from plants, algae, or agricultural waste products.

Differences in degradation

Download the fact sheet to learn more about plastics and bioplastics.

Biodegradable materials are those that can be fully broken down into natural substances, such as water and carbon dioxide, by naturally occurring microorganisms. In waste management, the term “biodegradable” is broadly used to describe materials that degrade either under composting conditions or in the natural environment. The key distinction is that compostable materials are designed to break down within a specific timeframe under controlled composting conditions, where factors like temperature, moisture, and microbial activity are optimised to accelerate decomposition and biomass formation.

Certified compostable

Compostable refers to a product’s ability to biodegrade into non-toxic, natural elements within a defined timeframe under specific composting conditions. Both fossil-based and bio-based bioplastics can be certified as compostable. However, compostability claims should only be made if the product has been certified to a recognised standard, such as Australian Standards AS 4736-2006 or AS 5810-2010.

Biobased bioplastic biodegradable

Smart sprays belong to this category.

Bioplastics made from bio-based feedstocks that fully break down into natural substances, either under composting conditions or in the natural environment. PHA bioplastics, in particular, are known to degrade effectively in both soil and marine environments.

Fossil-based bioplastic biodegradable

Fossil-based biodegradable plastics make up a relatively small category, which includes materials like PBAT and PCL. While PBAT is both biodegradable and compostable, improper disposal can still have environmental consequences, as its degradation requires specific conditions to occur efficiently.

Biobased bioplastic non-biodegradable

Bioplastics can be derived from bio-based

feedstocks while remaining non-

biodegradable. These materials are

chemically identical to traditional fossil-

based plastics.

Conventional plastics non-biodegradable

These materials do not biodegrade. In Australia, 2.9 million tonnes of plastic waste are discarded each year, with only 13% recycled, while the remaining 87% ends up in landfill.

Reference: State of Bioplastics in Australia, CSIRO, 2024 with permission.

Download the fact sheet to learn more about plastics and bioplastics.

News

SMART SPRAYS project teams up with UK scientists

Professor Daniel Murphy, from Murdoch University, travelled to the United Kingdom last month to collaborate with Dr Emily Cooledge and fellow soil scientists within Professor Davey Jones’ laboratory at Bangor University, Wales, as part of the SW WA Hub’s Transformational SMART SPRAYS project.

Transformational projects make strides towards agricultural resilience in WA

Six transformational projects led by the SW WA Hub and funded through the Future Drought Fund (FDF) are making meaningful strides toward long-term agricultural resilience in Western Australia.

The South-West WA Drought Resilience Adoption and Innovation Hub Hosts Successful Showcase and Field Tour

The South-West WA Drought Resilience Adoption and Innovation Hub hosted its inaugural Showcase and Field Tour on Wednesday and Thursday 11-12 December 2024. The event brought together farmers, grower groups, researchers, agribusinesses, and government agencies who are committed to enhancing the resilience of Western Australia’s agricultural sector.

SMART SPRAYS project featured in Facey Group’s ‘Drought Resilience in Action’ webinar series

In December 2024, Facey Group, the South-Eastern Wheatbelt Node of the SW WA Hub, invited PhD student Samantha Viljoen on their Drought Resilience in Action webinar series to talk about the SMART SPRAYS project. The video recording is now available.

New Bioplastics Innovation Hub houses SMART SPRAYS transformational project

Murdoch University and CSIRO launched the Bioplastics Innovation Hub on 2 September, an $8 million collaboration that will work with industry to develop a new generation of 100 per cent compostable plastic.

New Drought Hub projects set to transform agricultural practices

Six 18-month transformational agricultural projects have commenced in Western Australia after grants worth $1 million were awarded by the South‐West WA Drought Resilience Adoption and Innovation Hub (SW WA Hub).

Resources

Podcast | Making every drop count: innovations in water harvesting

How can we make the most of rain when it falls, and what alternatives exist when it doesn’t? In this episode, researchers Samantha Viljoen (Murdoch University) and Dr Priscilla Tremain (University of Newcastle) share their innovative work on improving water security in agriculture. Take a listen.

Collaborators

Contact

This project is being overseen by Professor Daniel Murphy, from Murdoch University, as part of the Bioplastic Innovation Hub, a partnership with CSIRO.

Professor Daniel Murphy

Director, Centre for Sustainable Farming Systems

Professor of Agricultural Microbiology, SoilsWest

Director, Bioplastics Innovation Hub

daniel.murphy@murdoch.edu.au

Lucy Tomassini

Project Manager, South-West WA Drought Resilience Adoption and Innovation Hub

lucy.tomassini@gga.org.au